Getting things right the first time is difficult.

When it was released in 1980, The Apple III computer had a wireboard that would become unbearably hot, it would crash when you tried to ‘save’, and it was totally unreliable and full of bugs. However, this first attempt at creating a computer allowed Steve Jobs and his team the chance to focus more clearly on what they were trying to achieve. A few years later, they had changed the industry with a series of brilliant and innovative products.

Henry Ford had two big flops before creating his third business – the Ford Motor Co. In doing so, he revolutionised the car industry. “Failure is the opportunity to begin again more intelligently,” he once said. Without testing the waters with his first two businesses, the Ford car would never have existed.

We’re not suggesting that we are the next Apple or Ford of the brewing world. Far from it. As home brewers, we’re just taking a leaf out of their book. We’re allowing ourselves the opportunity to make mistakes. We’re giving ourselves a chance to fail. But only so that we can be better.

There are currently two test batches of Road to Porty conditioning in Balegem. We added Scottish and Irish heather in both batches, but our Irish honey to only one, with the other getting a small dose of sugar. Recipe details will follow in later posts. Primary fermentation is complete after our test batch brew day on 31 January and last week we transferred both batches to carboys for conditioning with a plan to bottle in late March.

A few weeks of secondary fermentation in the bottle after that, we’ll be able to taste both versions of Road to Porty. This will give us the chance to really understand the flavour profiles of what we are creating and to work on any tweaks to the recipe for a bigger batch we’ll brew for Mike and Fiona’s wedding in September.

ROAD TO PORTY TEST BATCH

Here are some pictures from the brewing and conditioning of the test batch of Road to Porty so you can see how the project is coming along:

Mashing In

Timon stirs the mash while Franklin keeps an eye on the temperature.

Hi-Tech Temperature Control

Wrapping our mash tun to keep it at the right temperature. I assist Franklin tuck everything in.

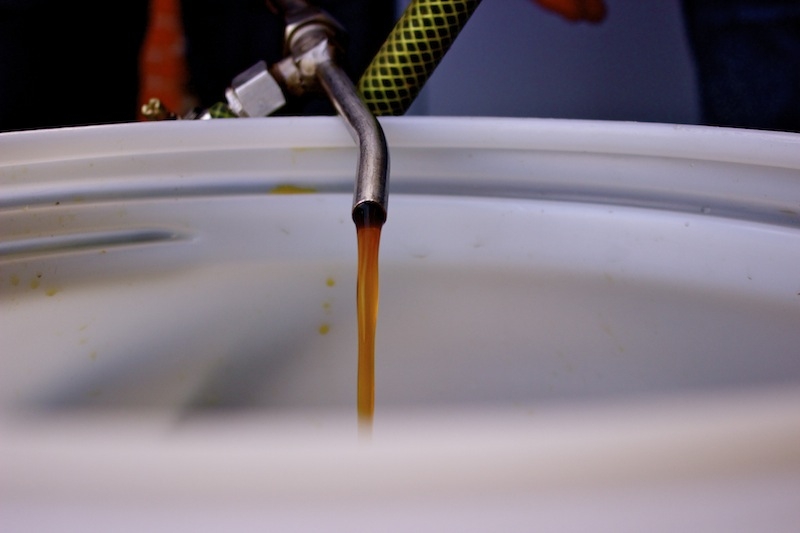

Transferring to the Kettle

Timon and Franklin transfer the wort to the kettle for boiling without spilling a single drop.

On the Boil

A watched kettle never boils. But we watched. And it boiled.

Hoppy Time

I add the hops while Timon watches on. We added the heather directly into the mix without a straining bag.

Oh Honey

Ben makes sure Franklin gets the correct amount of honey into one of the batches at flame-out. “Good honey”, says Franklin after licking his fingers clean.

Cool Kids

We cool the wort through a spiral wort chiller. Just look at that beautiful colour.

Yummy Wort

We admire the wort, and Franklin’s clogs.

Spent Heather

Heather flower remnants left in our kettle. We’re very curious to see what the heather will do to our beer.

Pitching Yeast and Fermenting

We put our yeast to work. The fermenter on the left is the honey batch (‘honing’) and the fermenter on the right is our sugar batch (‘suiker’).

Two Weeks Later: Transfer to Carboys

With primary fermentation completed after two weeks, we transfer the young beer to carboys for conditioning.

Conditioning Time

This now goes into Franklin and Kim’s cool beer cellar for a while to mature the beer and make sure we don’t have any unwanted flavours or harmful compounds.

Sharing a drink

We worked up a thirst, and we deserved a drink. All porters of course.

Tweety Porter

And here’s the process in tweets…..

Picked up some European interpretations of Porter for inspiration as we brew the test batch of #RoadToPorty on Sat. pic.twitter.com/gsZweWnyHI

— Belgian Smaak (@belgiansmaak) January 29, 2015

Brewing test batch #RoadToPorty with @audhumla101, @TimonvanGent, Ben and Kim. #BrewDay pic.twitter.com/Jtlw4tddC4

— Belgian Smaak (@belgiansmaak) January 31, 2015

Yeast pitched. Fermenters sealed. The #RoadToPorty test batch is alive! pic.twitter.com/GlZGIhuK5n

— Belgian Smaak (@belgiansmaak) January 31, 2015

Transferring the #RoadToPorty test batches to carboys today for conditioning. @audhumla101 @TimonvanGent pic.twitter.com/6wQcA05isn

— Belgian Smaak (@belgiansmaak) February 22, 2015